Products

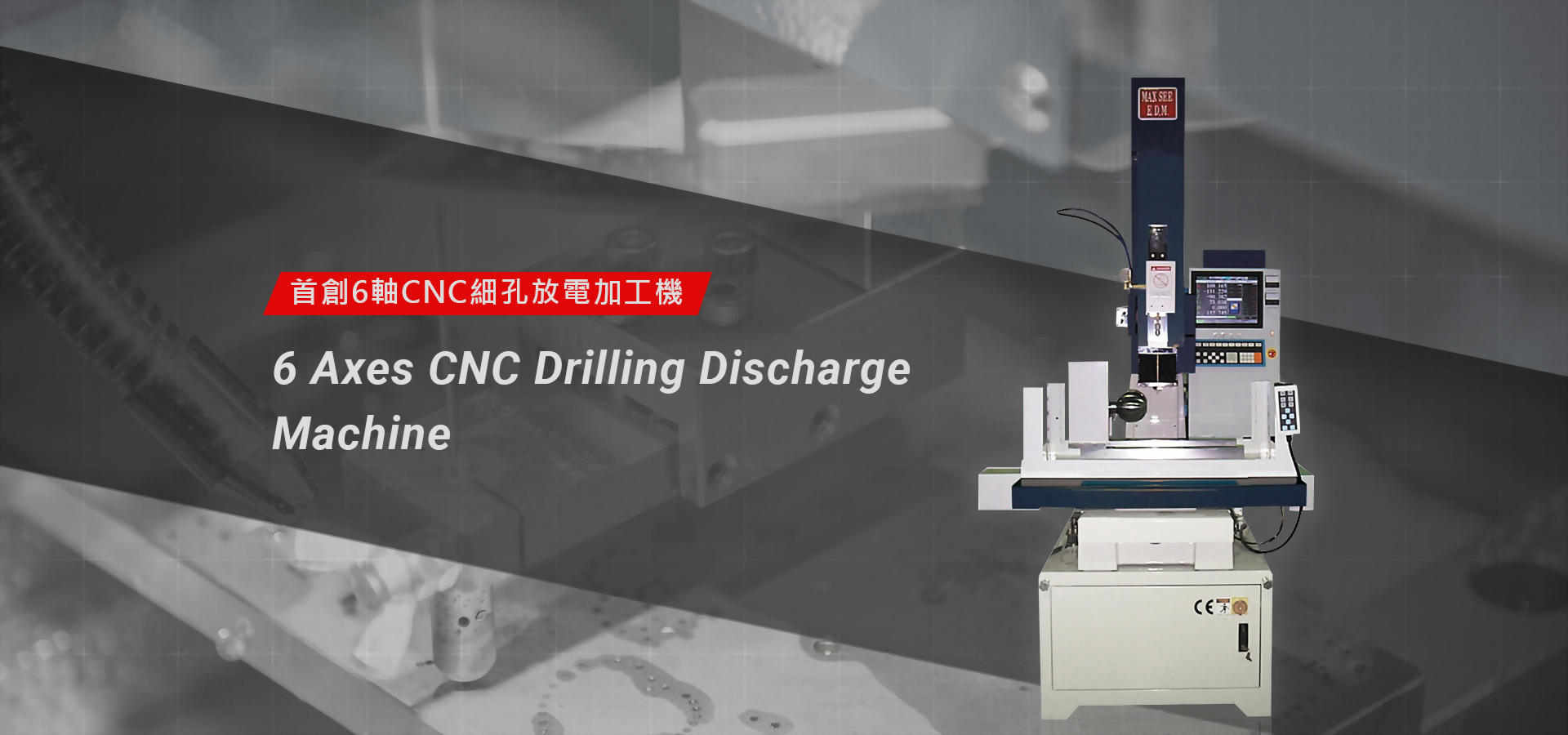

SDR56

● Multi-axis CNC controller

Extra installment for A-axis and B-axis is available.

● User Friendly Interface

Uses Windows CE operating system and features a 15-inch full-color touch screen.

Comprehensive functions on operating system, correct molds, and NC program

Drill CNC Series possess memory function for 2000 sets of processing depth setting.

● Auto Tool Changer、Auto Guide Changer

With the auto compensation of replacement new electrodes, and complete automation functions with ATC (Opt.) and AGC (Opt.) to save time cost.

● Abundant Machining Conditions

Meet a wide range of machining needs, comprehensive machining conditions to provide the combinations of various types of electrodes and workpieces.

Also be able to Machining a variety of metal materials, as well as any irregular shape.

FX600

● Superior Machining Function

Come with 12,000 RPM direct-drive spindle, spindle taper#40(DIN,BT,CAT) and 24-tool changer magazine

● Rigid construction

All major structural parts are manufactured by cast iron. Finite Element Analysis is conducted to optimize the machine structure to meet the requirement machining.

● High efficiency working table

The precision rotary tilt table allows for either 3+2 or 5 axis simultaneous machining.

BSW325

● Rigid construction

Rigid structure and fixed table design with FC35 fine grain castings reduce thermal distortion over long hour used and eliminate vibration during machining.

● AWT System (For BSW Series)

The threading with water jet can pass through the workpiece more than 200 mm thick. The hot-melt method is used to cut the wire, which creates the threading efficiency.

● User Friendly Interface

Uses Windows CE operating system, each operating module has multiple functions and features a 15-inch full-color touch screen for easy and convenient operation.

● High Precision Machining

The corner aid control module can set the corner machining conditions and weaken the speed, and execute in segments.

Exclusive dual trace system by 1μm linear scales and encoder, for high precision machining.

● Linear Motor (Optional)

Comparing with tradition ball screw structure wire machine, linear motor (Optional) has longer time accuracy persistence. Advantage of fast servo feedback, low wear, no gap and no temperature changes, which can improve the machining efficiency. With 0.05μm high resolution optical scales, it can reach the high precision result in fine machining.

ZNC-C26

● Programmable Z axis, automatically control depth and generator settings from roughing to finishing cycles

●1 micron resolution linear scales, provide closed loop and position feedback for precise part positioning accuracy.

● High Quality cast iron for increase rigidity and work piece capacity with heat treated work table.

● Special circuit for tungsten steel machining (Optional).

● Compact design saving up to 30% space by oil tank design in the based and generator attached with machine.