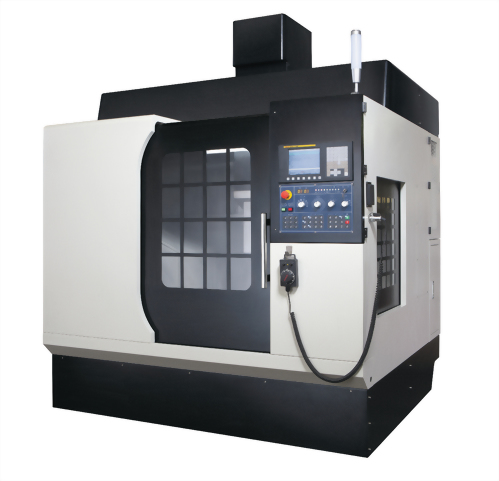

● High Speed Milling

Double column structure with ultra-low tool vibration and run-out. Come with 24,000rpm high speed spindle. Have ability to work with heavy/light machining on graphite (Opt.) and various metal materials and application.

● Self-developed Controller

Executing 1500 block per second and program pre-decode by 2000blocks. Automatic corner speed control offers high accuracy for work piece. High-speed and high-precision parameter setting, automatic monitoring of spindle status for automatic compensation; and easy selection of required machining items and input of data, can generate programs and quickly edit and operate. Instant spindle monitoring system calculates tool length and creates the compensation value automatically.

● High Accessibility

Compact design with small foot print and excellent operator accessibility to the machine work space reduces the operator’s load.

Double column structure with ultra-low tool vibration and run-out. Come with 24,000rpm high speed spindle. Have ability to work with heavy/light machining on graphite (Opt.) and various metal materials and application.

● Self-developed Controller

Executing 1500 block per second and program pre-decode by 2000blocks. Automatic corner speed control offers high accuracy for work piece. High-speed and high-precision parameter setting, automatic monitoring of spindle status for automatic compensation; and easy selection of required machining items and input of data, can generate programs and quickly edit and operate. Instant spindle monitoring system calculates tool length and creates the compensation value automatically.

● High Accessibility

Compact design with small foot print and excellent operator accessibility to the machine work space reduces the operator’s load.

| Item | unit | H56S | |

| X/Y/Z Travel | mm | 600 × 500 × 300 | |

| Work Table Size(L×W) | mm | 600 x 500 | |

| Max. Work Piece Weight | kg | 120 | |

| Work Table Configuration(T slot nominal dimension × spacing × number of T slots) | mm | 12 × 90 × 5 | |

| Distance From Table Surface To Spindle Nose | mm | 150~450 | |

| Power Input | 3 phase, 220V/380V | ||

| Rapid Traverse Rate | m/min | 30 (X.Y) , 20 (Z) | |

| Tool Magazine | position | 12/(16) | |

| Spindle Speed | rpm/min | 5000~24000 | |

| Spindle Motor | kw | 7.5 | |

| Spindle Taper Shank | BT-30 (HSK-E40) | ||

| Program Storage | M | 256 | |

| Machine Weight | kg | 3000 | |

| Machine Dimension | mm | 2500 × 1900 × 2440 | |